Thermography is a efficient preventive and predictive maintenance-be it mechanical or electrical.Thermography is the time- and cost-saving method for non-contact detection and analysis of thermal anomalies during maintenance

There was a time when maintaining & detecting problem areas in big production plants or industries & utilities was a tough job. However, the thermography or thermal imaging technique has revolutionized the complete predictive maintenance inspection cycle for all types of industries.

The commonly faced problems by most manufacturing industries & utilities are electrical fires & production downtime, something these industries just can’t afford. Thermography comes up as an effective solution for all such industries.

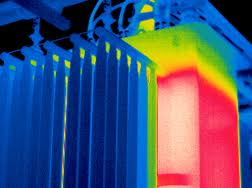

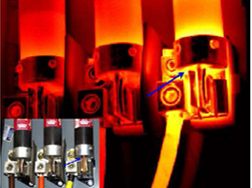

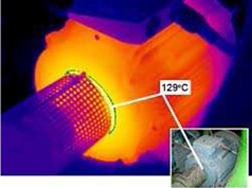

Thermal imaging cameras help in quick & accurate scanning of the entire surface of an electrical equipment or machinery to visualize the temperature differences in the form of thermal images. In manufacturing industries, thermography helps the maintenance experts in detecting problem areas & hot spots for preventing production downtime & major electrical fires. It can be applied to a wide range of electrical & mechanical equipments for detecting temperature anomalies, leakages, overheating, overloading, etc.

Thermography in utilities helps detect problems during power generation, distribution & transmission.

Infrared thermal imaging can not only be applied to the manufacturing industries & utilities, but also to facilities like hospitals, hotels & offices. It helps electrical contractors in scanning electrical connections & cabinets, that too in a non-contact mode that allows scanning objects for temperature differences without getting into danger.

Owing to this widespread application of thermography, it has contributed in a big way to substantial cost savings.